Automobiles are not only luxury these days but also a definition of an individual’s style. With such a wide variety of tints and shades of so many colours, people choose very specific shades which suit their style. Since, vehicles are long standing assets, applying automotive refinishes is the best way to preserve the outer surface and colour.

With this thought on mind, Painta Chem (India) manufactures great quality of automotive finishes to achieve best results.

To ensure best results on an auto body, the following is the basic workflow of auto refinishing process.

Cleaning the surface:-

Begin by completely removing the older coatings and bringing the substrate back in the form of a bare metal. For achieving this we can use PCI Paint Remover for metal surfaces. Use paint brush and hand gloves to safely apply paint remover all over the auto body. In sometime, old coat will start to swell. Completely remove that paint waste and thoroughly clean the surface with a soap and water wash followed by PCI degreaser to ensure metal is completely clean and free from grease, oil or any other contamination in older finish. Execute this step carefully as it is one of the most overlooked steps in auto body repair and causes the most aggravation when it comes to spray the new paint on the vehicle.

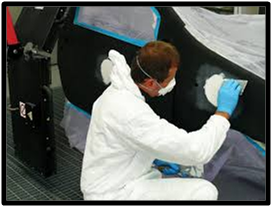

Repairing the surface:-

Deep dents should be completely removed before starting to get repaired. Little indentations or uneven surface can be treated by using quality body filler. PCI Lightweight body filler makes this task less tedious as it is easy to sand and long lasting. After applying body filler sanding plays the key role. Body filler should be sanded to make it even and smoother. Now, next comes in is polyester putty to straighten the panel. PCI polyester Putty helps in shaping up the panel which eventually lost its shape due to dent removal. Putty should always be applied in thin multiple layers and sanded between coats to promote proper adhesion. Once the putty has been applied, it must be sanded smooth. The more smooth it is, the less primer will be needed to fill the scratches that are left in the putty.

Get it primed:-

Now, that we have repaired and reframed the auto body we can proceed further and get it primed. This step is important to make sure that no indentations are left on the surface and it is smooth enough. Use of good quality of primer is highly recommended as it plays a key role here and fills the uneven surface if still left. PCI PU Primer surfacer is highly recommended as it is rust resistant, dries quickly, easy to sand and has excellent adhesion. Sanding of primer is done next to smoothen the surface. Block sanding is also done to ensure that the primer surfacer is blocked and good enough to proceed.

Apply base coat:-

Before applying base coat make sure that you properly wash and clean the auto body to remove sanding dust and other contaminants. Blow the area dry and wipe the area to be sure that all moisture and dust has been removed. Once you are sure you have a clean and dry surface then you may apply the base coat.

Painta Chem (India) offers a wide variety of finishes for base coats such as PU based solid base coats, metallic base coats, Matte finishes, Satin finishes and many more. Refer PCI tinting guide to choose the high quality base coats.

Before applying base coats kindly check the gun setting and air pressure of the compressor. Appropriate thinning of the paint is also required for which good quality thinner should be used. PCI T-018 grade of thinner is highly recommended. Now apply the base coats and leave them to dry. Proper drying between the coats should be maintained for best results. Soft wet sanding is recommended to get rid of little dust particles if any before applying the top coat.

Apply the top coat:-

Now is the time to achieve the last and final step i.e. applying top coat. PCI PU Clear is a highly recommended topcoat which have best features such as:

- Excellent chemical resistance and UV resistance

- Great adhesion

- Mirror like glossy finish

- Non yellowing property

- Scratch free

- Long life and flexible.

Mixing ratio of base and hardner should be taken care followed by dilution ratio and also apply top coat in a dust free zone or a proper ventilated paint booth for best results.

Leave it to dry, proper drying time should be taken care of before final rubbing and polishing..