Epoxy Coatings

Epoxy Casting Lacquer

Epoxy casting lacquer is a two component solvent less high quality epoxy coating with water white curing agent who is mainly used in casting, general adhesives & other industrial products.

Technical Data

- A: B 2:1

- Coverage: depends on the thickness of the film.

- Drying Time: Tack free time ≈ 2 hrs. | Hard Time= 3-4 hrs. | Complete curing overnight

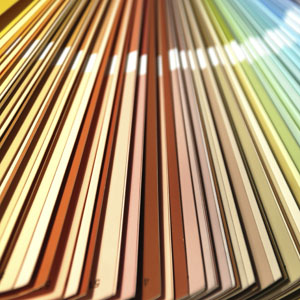

Epoxy Clear & Epoxy Paints

Epoxy clear & epoxy paints are high quality two component paints specially formulated to cure at room temperature. Epoxy top coat has outstanding chemical resistance with high gloss and excellent hardness. It gives adhesion to many substrates, excellent flexibility & abrasion resistance.

Technical Data

- A: B 4:1

- Coverage: depends on the thickness of the film.

- Drying Time: Tack free time ≈ 20 Mins | Hard Time= 3-4 hrs. | Complete curing overnight

Epoxy Thermosetting Clear

Epoxy Thermosetting clear is a single component clear cured at elevated temperature. ETC has very high resistance to water, detergents, mild acids & alkalis, chemicals & solvents. It has good flexibility, abrasion resistance, colour retention, excellent corrosion resistance & improved surface adhesion.

Polyurethane Coatings

PU Glass Coat

P.U. Glass Coat is a two component premium quality coatings,

specially Formulated to coat on glass items. PU Glass Coat has

excellent weather resistance. It shows excellent resistance to water,

salt water, alcohol, oil & grease.

Technical Data

- A: B 9:1

- Coverage: depends on the thickness of the film.

- Drying Time: Tack free time ≈ 10 Mins | Hard Time= 2-3 hrs. | Complete curing overnight

PU Standard Top Coat

PU Std. Top Coat is two component systems designed to cure at room temperature. It consists of Base component & Hardener component which on mixing form tough film with outstanding durability, chemical & weather resistance. An effective Top Coat for petrochemical refinery and fertilizer industries. The system is useful for maintenance coating, structural coating as well as for floor coating.

Technical Data

- A: B 9:1

- Coverage: depends on the thickness of the film.

- Drying Time: Tack free time ≈ 10 Mins | Hard Time= 2-3 hrs. | Complete curing overnight

Acrylic Coatings

Acrylic Thermoplastic Top Coat

It is a premium quality Acrylic clear suitable for silver, glass, brass & other metals. It gives non-yellowing, flexible, high gloss film on substrate.

Technical Data

- Coverage: depends on the thickness of the film.

- Drying Time: Tack free time ≈ 5 Mins | Hard Time= 2-3 hrs. | Complete curing overnight

Acrylic Thermosetting Top Coat

- Non yellowing with High Gloss & Clarity

- Low thinner intake and better DFT build up.

- Excellent Outdoor Durability.

- Very Good Mark Resistance

Technical Data

- Coverage: depends on the thickness of the film.

- Curing Time: 20-25 mins. At 120°C.

Heat Resistant Paints

These coatings are specially developed for various applications such as tractor silencers, two wheeler silencers, automobile silencers, generators, barbeques, etc where high temperature requirements are prevalent.It is easy for application and suitable for external application with good corrosion resistance after achieving high temperature and has lower voc.

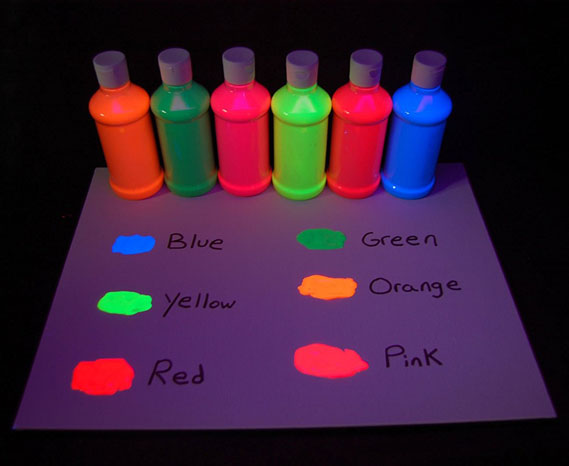

Fluorescent Coatings

We offer superior quality daylight fluorescent coatings.

Phosphorescent Coatings

Phosphorescent coatings characterized by their ability to absorb and store the energy of natural/artificial light and slowly emit it in the form of visible light in the dark. The cycle of absorbing, storing and emitting is practically infinite. The afterglow phenomenon is also referred to as phosphorescence and hence these coatings are also known as phosphorescent (Glow-in-the-Dark) coatings.

Infra-red Reflecting Paints

Infra-red reflecting (IRR) paints are functional colorants which have the capability to reflect the infra-red radiation. 49% of the sun’s energy is composed of infra-red radiation. This infrared radiation is solely responsible for generating heat.

IRR Paints prevent expansion and degradation due to heat and extend service life of products.

It reduces air conditioning costs due to reduction in “heat-island” effect.

Retro Reflective Coatings

Retro-Reflective Pigments are comprised of aluminum coated spherical glass beads and strongly reflect the incident light.